The 1100 Series conveyors from Dorner offer production engineers and machine builders the thinnest standard frame on a mass produced belt conveyor available.

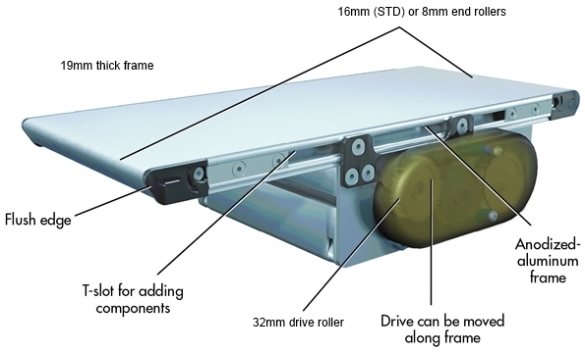

It measures just 19mm frame depth and can fit in tight spaces inside machinery and also help free up room for other machines or access by operators.

The conveyors have anodised-aluminium frames, FDA-approved plastic bearing housings and stainless-steel fasteners.

This means the conveyor belt qualifies for Clean Room Class 100 certification.

This makes these small conveyor belt systems suitable for medical, pharmaceutical, life-science applications and industrial use.

This design is optimised for small parts and features 16mm rollers at each end on the centre drive unit shown here.

This allows for small parts roller transfer for accurate and efficient product transitions from the conveyor to a machine or another conveyor.

The belt is almost flush with the frame, thus enabling side transfer of products.

The belt is also tracked and kept in line by the pinch drive and conveyor frame.

The central pinch drive, which can actually be located anywhere along the length of the conveyor, handles 7kg loads without needing high belt tension.

Loosening four fasteners on the drive lets it separate into two halves, making belt change simple and fast.

These conveyor belt systems come with fixed-speed ac or brushless-dc gear motors.

The brushless gear motor offers forward and reverse, as well as 60 indexes/min.

The belt speed is adjustable up to 21M/min and belts come in widths from 45mm to 250mm.

Conveyor lengths go from 266mm to 1524mm in 3mm increments.

For more information on conveyor belt systems go to http://www.asconveyorsystems.co.uk/Conveyor-Belts.html