Traditionally when a long narrow product is to be transported, metal chains and wherever relevant, rollers have always been used.

Usually the longer the product the more lanes would be necessary to transport the product without it sagging and creating quality problems and well as conveying issues.

These conveyors would usually have a common drive shaft and this drive shaft would ensure that the conveyor lanes travel at the same speed.

Failure to do this will result in uneven conveying.

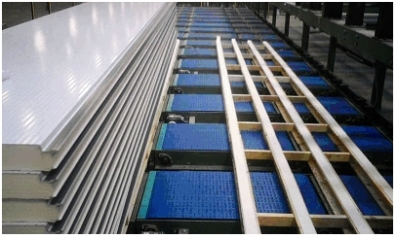

An interesting new option might now be to adapt the wide modular plastic belt conveyor to work together in a similar way.

The advantages are that the modular belt is positively engaged in sprockets to provide drive, but also the wider nature of these conveyors helps to reduce product sag between lanes.

Details can be found shortly at http://www.asconveyorsystems.co.uk/Modular-Plastic-Conveyors.html