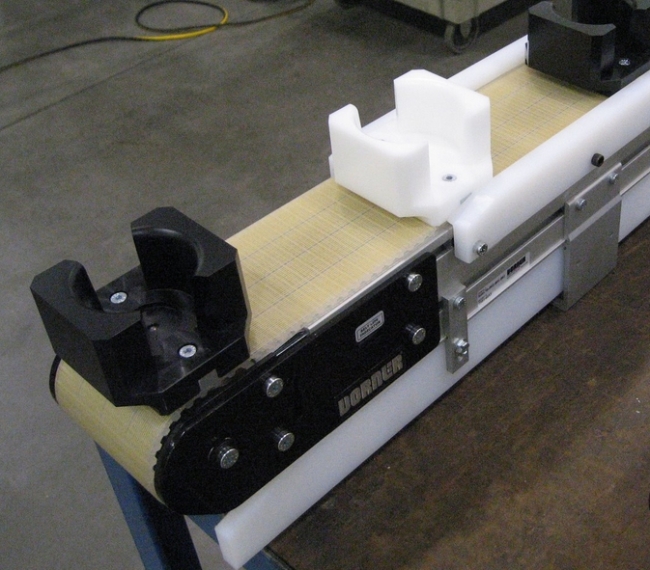

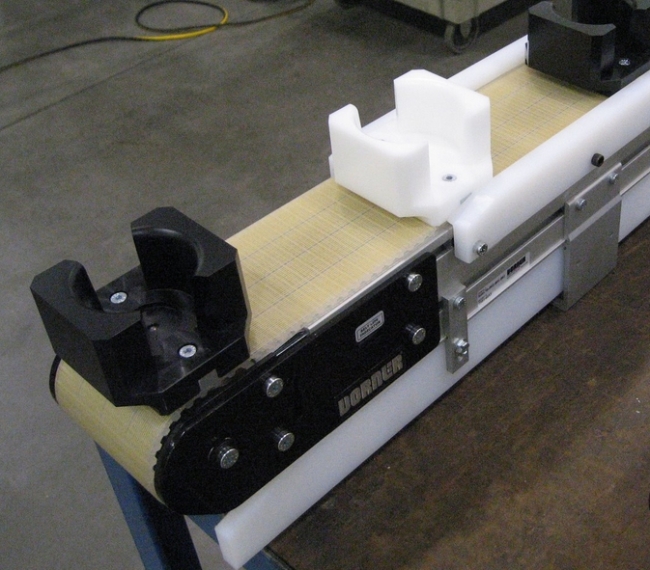

This is a picture of a recent order where the customer r equired accurate positioning of a product on a conveyor belt system so that processes could be carried out.

equired accurate positioning of a product on a conveyor belt system so that processes could be carried out.

equired accurate positioning of a product on a conveyor belt system so that processes could be carried out.

equired accurate positioning of a product on a conveyor belt system so that processes could be carried out.The precision of the positioning required was such that positioning the product on a normal conveyor belt was not going to be possible. The product was an irregular shape and would not sit correctly on a flat belt, not enough for the process to be carried out.

At one time this situation would have called for a special design chain or slat conveyor with metal attachments, or even possibly a robot to present the product rather than a lower priced conveyor system.

Now that we offer the Dorner precision drive conveyor systems, we can give the customer the positional accuracy of a timing belt construction with no slip and guaranteed position.

An additional advantage is that the timing belt is so tough that it can be drilled and attachments can be screwed to the belt. Here you can see that the plastic cradles for the product to sit in are custom machined for the product to sit on the fixture in the right orientation and the fixture itself is screwed down to the belt.

The best of both worlds from a standard 3200 series belt conveyor package.

For more information on mini conveyor belt systems go to http://www.asconveyorsystems.co.uk/Timing-Belt-Conveyors.html