3200 Series Conveyors are best for:

- Parts Handling

- Transfers

- Accumulation

- Precision Parts Movement

- Part Incline/Decline Routing (Z Frames)

- Positioning

- Automated and Manual Assembly

- High Speeds

- Long Runs

- Mainline Packaging

Benefits of 3200 Series Belted Conveyors:

General Specifications:

- Flat Belt End Drive, Cleated Belt End Drive, Center Drive, and iDrive® models

- Widths up to 48 in. (1,219 mm) (Wider widths available, consult factory)

- V-guided belt tracking

- Lengths 30 in. (1,219 mm) – 99 ft. (30,175 mm) depending on drive selection

- Speeds up to 600 ft/min (182 m/min)

- One of our heavy duty belt conveyors handling loads up to 1,000 lbs (455 kg)

Applications:

- Parts Transfers

- Part Accumulation

- Precision Part Movement

- Part Incline / Decline Routing

- Part Handling and Positioning

- Automated and Manual Assembly

Benefits of 3200 Series iDrive Conveyor:

General Specifications:

Belt Widths: 6″ (152 mm) to 24″ (610 mm)

Conveyor Lengths: 3′ (914 mm) to 12′ (3,658 mm)

Belt Speeds: Variable Speed, (3) Speed Options

Conveyor Load Capacity (non-accumulated, distributed load) from 52 to 120 lbs. See manual for more details

Indexing Capable: Up to 30 indexes per minute

Duty Cycle: Continuous rated

Built-In / fixed acceleration and deceleration

Multiple Control Models

V-guided belts for maintenance free belt tracking

Maintenance free sealed bearings

Grease filled sealed for life planetary gear boxes

Maintenance free brushless DC Motor

3200 Modular Belt Conveyors

Benefits of 3200 Series Modular Belt Conveyors:

- Flush tail design locates bearing inside frame to fit in tight spaces

- All belts fully contained in UHMW guiding for maintenance free tracking

- Patented sprocket alignment key for worry free belt maintenance

- Dual t-slot or patented Smart Slots® for flexibility and clean sided applications

- Inboard type frame connection joint improves strength while keeping t-slots open

- Stand mounts lock in into the frame for strength and durability, yet movable anywhere along frame length

- Optional integrated power transfers for small part handling

- Flexible belt containment system allows for tab or bearing retention method for up to 4 corner modules

Sizes & Measurements

- Belt widths: 6″ (152 mm) to 48″ (1219 mm)

- Conveyor lengths: 36″ (914 mm) to 999″ (25,375 mm)

Loads & Speeds

- Loads up to 1000 lbs (455 kg)

- Belt speeds up to 400 ft/min (122 m/min)

Conveyor Configurations

- Straight

- Z-Frame

- Curve

- Nose-Over

- Horizontal to Incline

Belt Types:

- Flat Top

- Flush Grid

- Friction Inserts

- Cleated

- Roller Top

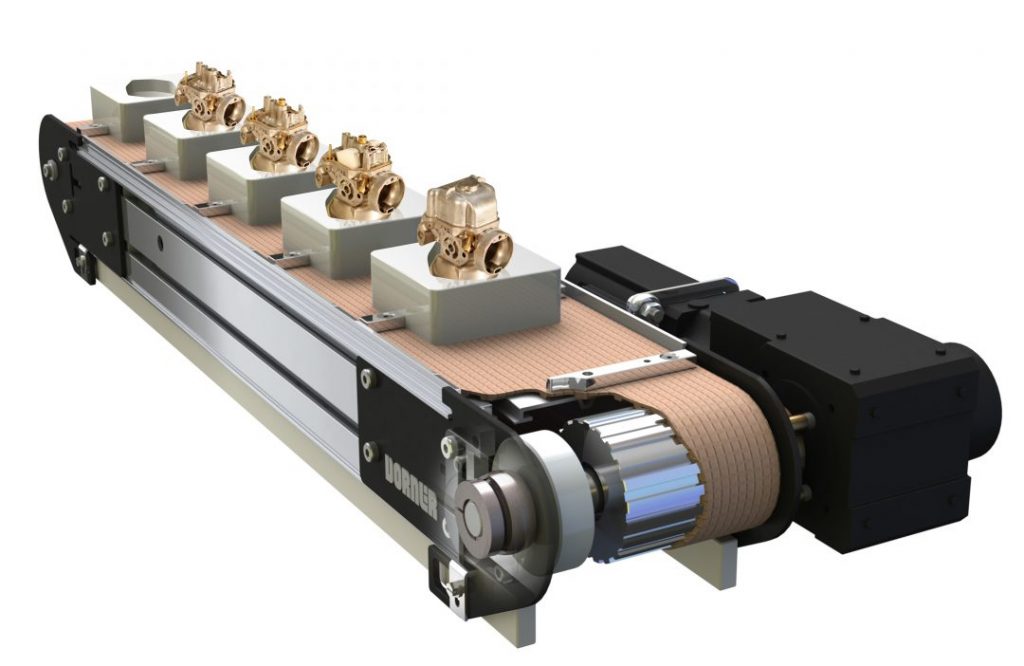

- Precision Move Precision Move with Fixtures

Curved Modular Belt Types

- Basic Single Curve

- Low Backpressure Roller Top Curve

- Friction Insert Curve

- High Strength Tab Curve

- High Strength Bearing Curve

3200 Precision Move Conveyors

Benefits of 3200 Series Precision Move Conveyors:

Specifications:

- Loads up to 750 lbs (340 kg)

- Belt speeds up to 517 ft/min (158 m/min)

- Belt widths: 4” (95 mm) to 18” (457 mm) in 2” increments

- Conveyor lengths: 2’ (610 mm) to 50’ (15,240 mm)

- 21 tooth H (1/2”) pitch profile timing belt (10 mm Metric pitch available)

- 3.3” (84 mm) pitch diameter drive and idler pulleys turn approximately 10.5” (267 mm) of belt per revolution

- Optional M5 belt inserts

- Optional pallet mounting bars, 5/16” x 1/2” plated steel

- Conveyor package w/ servo motor index repeatability ± 0.02”

- 100 Indexes per minute rated

Features & Benefits:

- High load capacity urethane belting with kevlar cords (True Timing Belt)

- No capacity drop when pushing belt

- All widths feature a single belt for increased mounting flexibility

- Positive drive no slip belting and side guides provide worry free belt tracking

- Use optional cleats to create pockets for controlled part flow

- Minimum pallet mounting bar is spacing 1” in length

- T-slots make mounting accessories simple with no drilling or special tools

- Compatible with standard drive packages

- Available with servo motor and mounts for increased accuracy of index

- Servo package includes fully integrated solution with intuitive PC interface

- Sealed ball bearings

For more information email info@asconveyorsystems.co.uk or ring 01772 690656.